The Greatest Guide To American Plastics

The Definitive Guide for American Plastics

Table of ContentsExcitement About American PlasticsThe Single Strategy To Use For American PlasticsAmerican Plastics - An Overview4 Simple Techniques For American PlasticsSome Of American Plastics

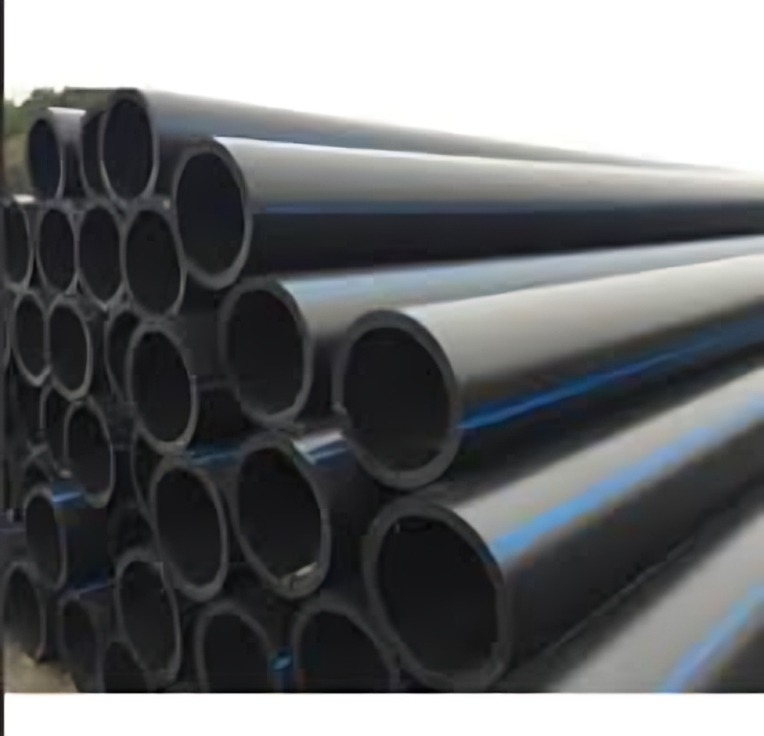

A little research can help you with time. It is hard to evaluate its top quality initially glance with the appearance of HDPE pipeline installation, many flaws are revealed when using, so we can only have a proper judgment after use. For that reason, it is necessary to pick HDPE pipe fittings made by an expert producer with a great credibility and credibility.

A technological expert is necessary for a great product, specifically in the manufacturing sector, since a tiny mistake will certainly cause the failing of the entire job. HDPE pipes can change concrete pipelines in field systems to save time and expense of fixing busted or ruptured pipes. HDPE pipeline is also a cheaper alternative contrasted to other piping products in regards to operating and setup expenses.

What Does American Plastics Mean?

HDPE pipes are made with strong straight or curved sections. The pipelines are not brittle and can be conveniently put right into a curved location without additional jointing or welding.

Chemicals resistant to HDPE pipes can pollute the pipeline. The pipe does not work with chemicals and does not burn warm or electrical energy.

HDPE pipes are normally solid and immune to damages brought on by outside loads, high pressure or resonance - https://www.intensedebate.com/people/americanplastic. The pipes can endure handling and bend also in winter. Safe eyeliner HDPE inner tubing Smooth Line Pipe Moving lining using roller combinations Pipe surge Plastic pipes systems Construction of brand-new pipelines Rust resistance, no leaking, high resilience

Warmth combination, while its challenges exist, can create solid and reputable joints. Responses: The toughness and sturdiness of HDPE can be measured by its ability to endure temperatures of around 248F in the brief term or perhaps a consistent 230F. If your application includes gas and liquid to access and raise those temperature levels, HPDE piping is a dependable service.

10 Easy Facts About American Plastics Described

A drinkable water line/potable water pipeline is always dark with blue red stripes and pipes passing via fluids, fluids under stress, and procedure gases are always filled up with a yellow or black coat with yellow lines. HDPE pipeline product have actually been used in the general industry for over half a century and their results are astounding, constructing self-confidence amongst makers that they are a lot more concentrated on HDPE pipeline solutions.

Times because 1991 Elimination of material needs with scale and modification. In the stress and anxiety fracture resistance test the cellular division demands were deteriorated. It is reasonable to conclude that HDPE pipe built today might have.

Each dimension group is made maintaining in mind the needs of pressure, flow rate, and environmental aspects of the desired application. By matching the right HDPE pipeline size to its use, designers and contractors can optimize efficiency and expand the life expectancy of their piping systems. Dimension and size are related concepts in the context of HDPE pipes.

American Plastics - An Overview

As mentioned earlier, pipes with reduced SDR worths have the ability to endure greater stress, which is an important factor to consider in the choice procedure for tasks that involve high stress or essential pop over to this site applications. high quality hdpe pipe. Choosing a pipeline with an improper SDR could lead to system failure, safety risks, and expensive repairs. Picking the proper HDPE pipe size is crucial for the success and effectiveness of any type of piping system

Application Specifics: Tailor your pipe dimension option to the certain needs of its application, whether for municipal, commercial, or various other uses. Comprehending how the HDPE pipe will be used, the awaited flow prices and the pressure demands are essential. As an example, high-pressure applications might need a pipeline with a greater wall surface density to hold up against the interior stress and anxieties, while a lower-pressure, high-flow system could focus on diameter dimension to reduce friction loss.

American Plastics Can Be Fun For Anyone

Comply with these steps: Assess the Application: Figure out the pipeline's intended use, including environmental elements and service problems. Refer to SDR: Inspect the typical dimension proportion to locate a pipeline that can handle the required pressure.

Picking the right HDPE pipe size is a fragile equilibrium between many technical requirements and practical requirements - https://www.ted.com/profiles/50224285. With careful factor to consider and accurate estimations, you can make sure the size of the pipeline you choose will serve your demands successfully and successfully. Selecting the correct HDPE pipe dimension is important for system efficiency, toughness, and cost-effectiveness

Recognizing these facets will make sure optimal efficiency and compatibility throughout your piping system - Texas hdpe pipe manufacturer. The awaited flow price or volume of the liquid being moved is just one of the main factors in pipeline dimension selection. A pipeline that is also tiny can restrict circulation, causing pressure loss and potential clogs, while an excessively huge pipeline might result in unneeded expense and decreased system performance